As pickleball continues to gain global popularity, the industry is witnessing rapid advancements in paddle manufacturing. The demand for high-performance, durable, and lightweight paddles has led to the exploration of innovative materials and cutting-edge production techniques. In 2025, several key trends are shaping the future of pickleball paddle manufacturing, with manufacturers like Dore Sports at the forefront of these changes.

1. Carbon Fiber Reinforcement Becomes the Standard

One of the most significant advancements in pickleball paddle technology is the widespread adoption of carbon fiber. This material is known for its strength-to-weight ratio, offering players a powerful yet lightweight paddle. Traditional fiberglass paddles are now being replaced by carbon fiber-reinforced versions, which provide greater durability, enhanced control, and increased spin potential.

Dore Sports has responded to this trend by integrating high-modulus carbon fiber into their latest paddle designs. By optimizing the fiber placement and layering techniques, they have developed paddles that offer superior stiffness and responsiveness, catering to both amateur and professional players.

2. Kevlar and Graphene: The Next-Gen Power Materials

While carbon fiber dominates the market, new materials like Kevlar and Graphene are emerging as game-changers. Kevlar, commonly used in bulletproof vests, is now being tested in paddle manufacturing for its shock-absorption and impact resistance. This results in a paddle that not only delivers power but also minimizes vibrations, reducing the risk of player fatigue.

Similarly, graphene-enhanced paddles are making waves in 2025. Graphene, one of the strongest materials in the world, allows for extremely thin and lightweight paddle cores without compromising durability. Dore Sports has been experimenting with graphene-infused polymer cores to create paddles that maximize control and maneuverability.

3. Thermoformed Technology for Enhanced Performance

Another breakthrough in pickleball paddle manufacturing is thermoformed technology, which involves heat-pressing multiple layers to create a seamless and more durable structure. This method improves paddle consistency, ensuring a uniform playing surface with better ball response and reduced dead spots.

Dore Sports has adopted advanced thermoforming techniques, allowing for precise weight distribution and improved paddle longevity. This innovation helps players maintain consistent performance over extended periods, making paddles more reliable and long-lasting.

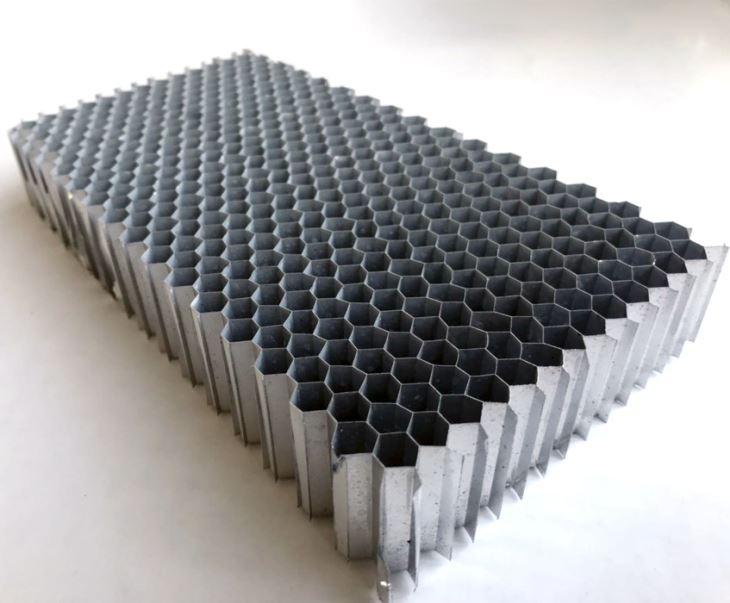

4. Honeycomb Core Evolution: From Polypropylene to Advanced Composites

Most modern paddles feature a honeycomb core, traditionally made from polypropylene. However, in 2025, new composite core materials are emerging, offering better energy transfer and durability. Hybrid cores that combine polymer blends with foam or Kevlar reinforcement are gaining popularity.

Dore Sports has upgraded its honeycomb core designs by integrating multi-layer composite cores, providing an optimal balance of power and control. These innovations cater to different playing styles, offering customized solutions for recreational and competitive players.

5. Eco-Friendly and Sustainable Manufacturing Practices

With increasing awareness of environmental sustainability, eco-friendly materials and production methods are becoming a priority for manufacturers. Recyclable carbon fiber, bio-resin coatings, and sustainable wood handles are being integrated into modern paddle production.

Dore Sports has made significant strides in adopting green manufacturing processes. The company has reduced its carbon footprint by implementing energy-efficient production methods and recyclable materials. Additionally, they have launched a recycling program that allows players to return old paddles for eco-friendly disposal.

6. Smart Paddles with AI-Driven Performance Tracking

Technology is playing an increasingly important role in sports equipment, and AI-powered smart paddles are one of the most exciting developments. These paddles come equipped with motion sensors and impact tracking technology, allowing players to analyze their game in real time.

Dore Sports is exploring partnerships with tech companies to develop smart paddles that provide feedback on shot speed, spin rate, and impact zones. This innovation is expected to revolutionize training methods and player performance analysis.

The pickleball paddle industry is undergoing a transformation, driven by advanced materials, innovative manufacturing techniques, and smart technology. Manufacturers like Dore Sports are embracing these changes to produce paddles that are lighter, stronger, more durable, and technologically enhanced.

With the rise of carbon fiber, graphene, Kevlar, thermoformed technology, sustainable production, and smart paddles, 2025 is set to be a landmark year for pickleball paddle manufacturing. As competition increases and player demands evolve, companies that invest in research and innovation will continue to lead the market.

As a one-stop pickleball product supplier, D...

As a one-stop pickleball product supplier, D...

As a one-stop pickleball product supplier, D...