In the world of padel and pickleball, the choice of materials used in racket manufacturing plays a critical role in determining performance, durability, and overall player experience. With increasing technological advancements and evolving market demands, manufacturers like Dore Sports are adapting their strategies to stay ahead. From traditional carbon fiber to new hybrid composites, let's explore the different materials used in racket production and how manufacturers decide on the best fit for the market.

Material Comparisons in Racket Manufacturing

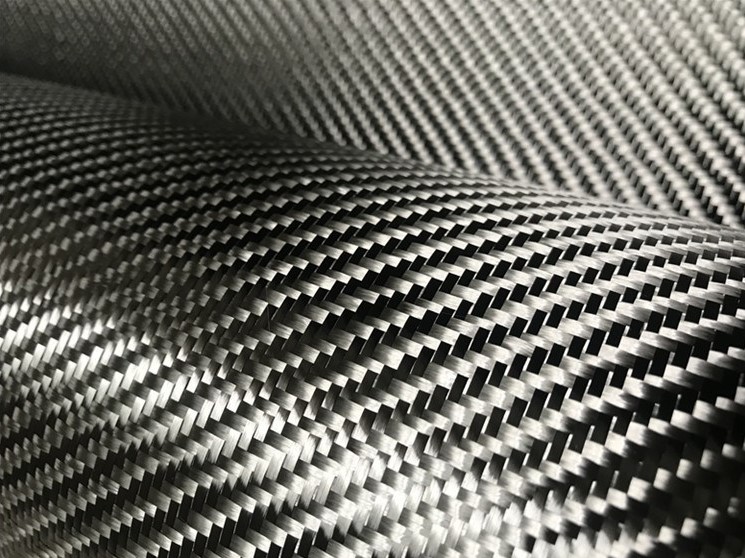

1. Carbon Fiber: The High-Performance Choice

Carbon fiber is one of the most commonly used materials in high-end rackets. It is lightweight yet extremely strong, providing excellent power and control. Many professional players prefer carbon fiber due to its stiffness, which enhances shot precision. However, the high cost of carbon fiber makes it less accessible to casual players.

2. Fiberglass: The Affordable Alternative

Fiberglass is another popular material, known for its flexibility and affordability. Compared to carbon fiber, it provides a softer touch, making it suitable for beginner and intermediate players. While it may not offer the same level of durability and power as carbon fiber, its cost-effectiveness makes it an attractive option for budget-conscious consumers.

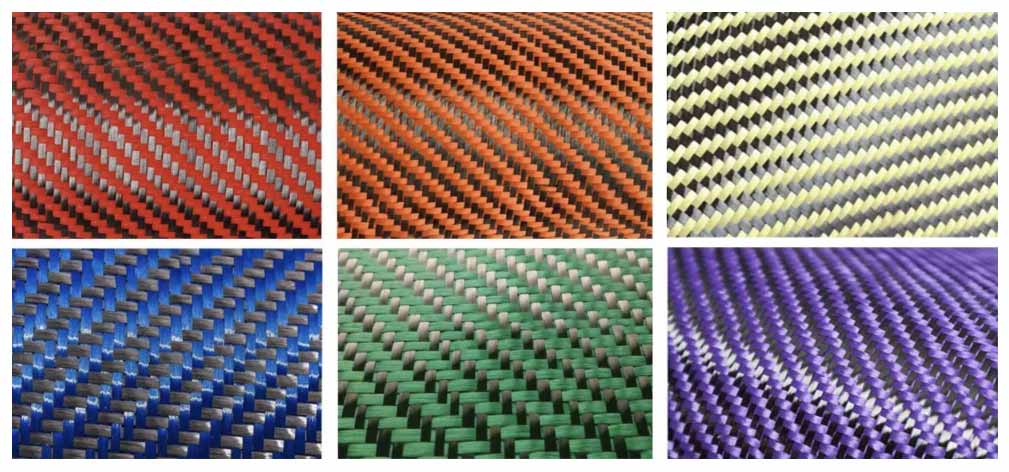

3. Kevlar and Hybrid Composites: The New Innovations

To balance performance and cost, some manufacturers are now using Kevlar and hybrid composites. Kevlar is known for its shock-absorbing properties, making it ideal for players looking for comfort and reduced vibrations. Hybrid rackets often combine carbon fiber with Kevlar or fiberglass, offering a mix of power, durability, and comfort.

4. Polypropylene and Polymer Cores: Enhancing Playability

For the core materials, manufacturers often choose between polypropylene honeycomb structures and other polymer-based cores. These materials impact the overall feel of the racket, influencing power and control. Polypropylene cores, for example, are lightweight and provide better touch, making them a preferred choice for professional players.

Dore Sports’ Innovations and Market Adaptations

To keep up with the fast-changing market and the latest technology, Dore Sports has implemented several innovative strategies in material selection and production:

1. Expanding Material Options – Instead of relying solely on carbon fiber or fiberglass, Dore Sports has introduced hybrid rackets using Kevlar, basalt, and advanced polymer cores to enhance player performance while controlling costs.

2. Customized Solutions – Recognizing the diverse needs of players, Dore Sports offers customization options where clients can choose specific materials, surface textures, and core structures. This helps meet the varying demands of different player levels and regional markets.

3. Advanced Manufacturing Techniques – The company has adopted new molding technologies that improve racket durability and consistency while optimizing weight distribution for better balance and control.

4. Eco-Friendly Production – With sustainability becoming a growing concern, Dore Sports is researching recyclable and eco-friendly materials that maintain high performance while reducing environmental impact.

5. Cost Optimization Strategies – By leveraging bulk purchasing agreements and local material sourcing, Dore Sports effectively balances quality and cost to provide competitive pricing without sacrificing performance.

How Manufacturers Choose the Right Material

The choice of materials depends on several key factors:

• Target Market: For premium players, high-quality carbon fiber is preferred, while beginners and recreational players often look for affordability with fiberglass or hybrid materials.

• Performance Requirements: If power and stiffness are priorities, carbon fiber is the go-to material. If comfort and vibration absorption are important, Kevlar or hybrid composites are ideal.

• Durability vs. Cost: Manufacturers must balance the lifespan of a racket with its price. While carbon fiber lasts longer, its cost may not be justified for casual players.

• Technological Advancements: New material innovations, such as graphene-infused surfaces or vibration-dampening cores, are continuously shaping the market.

As the padel and pickleball industry continues to grow, manufacturers must make strategic choices regarding materials to cater to different player needs. Dore Sports is at the forefront of this evolution, integrating new technologies and customized solutions to ensure that their rackets meet both professional and recreational demands. By focusing on innovation, customization, and sustainability, Dore Sports is setting a new standard in the industry, ensuring that players get the best possible experience with every game.

As a one-stop pickleball product supplier, D...

As a one-stop pickleball product supplier, D...

As a one-stop pickleball product supplier, D...