Padel has become one of the most exciting sports in recent years, with increasing numbers of players seeking high-quality rackets to enhance their game. At Dore-Sports, we take immense pride in crafting premium handmade padel rackets that combine both tradition and innovation. As a factory specializing in both manufacturing and trade, we offer not only exceptional rackets but also a full range of customizable accessories, providing our clients with a comprehensive solution for their padel needs.

Step 1: Material Selection and Quality Control

The first step in creating a high-quality padel racket is selecting the right materials. The core of the racket is typically made from EVA foam, polyethylene, or a combination of both. These materials ensure the racket offers a balance between control, power, and durability. The frame is usually crafted from carbon fiber or fiberglass, providing the ideal combination of lightweight strength and flexibility. At Dore-Sports, we ensure that only the highest-quality materials are used in every racket we produce.

Step 2: Shaping the Core

After selecting the materials, the core of the racket is precisely shaped to meet the specific design requirements. Our skilled craftsmen use cutting-edge technology to cut the core into the desired size and shape, ensuring optimal performance and balance. For custom orders, clients can choose from different core thicknesses and materials, allowing them to tailor the racket’s feel to their individual preferences.

Step 3: Constructing the Frame

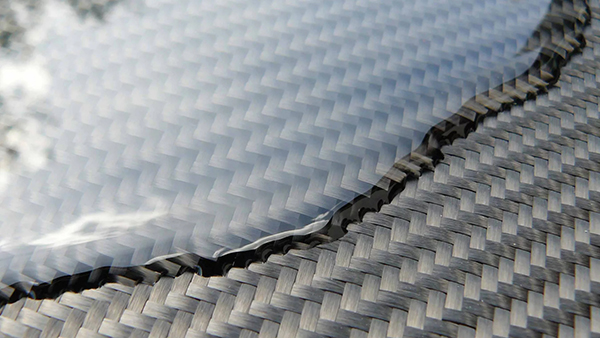

The frame is a crucial component of the padel racket. At Dore-Sports, we use advanced molding techniques to create a robust, yet lightweight frame. Carbon fiber is the material of choice for high-performance rackets due to its strength and ability to absorb shock, while fiberglass can be used for more flexible and durable options. The frame is carefully constructed to fit perfectly with the core, ensuring the racket’s overall strength and balance.

Step 4: Surface Layer Application

Once the frame is ready, the surface layer is applied. This layer is typically made from fiberglass or carbon fiber, offering additional control and a responsive feel. At Dore-Sports, we offer various customization options, from custom logos and colors to unique textures, enabling our clients to create a truly personalized racket that reflects their style.

Step 5: Assembly and Final Quality Check

After the core and frame are set, the handle is added, ensuring a comfortable and secure grip. We use premium materials like rubber or cushioned grips to enhance comfort and prevent slippage during play. Each racket undergoes a rigorous quality inspection to ensure it meets our high standards of performance, durability, and craftsmanship.

Step 6: Packaging and Custom Accessories

Before the rackets are shipped to our clients, we carefully package them to ensure they arrive in perfect condition. At Dore-Sports, we offer a full range of customizable accessories, including grips, covers, bags, and more. Clients can choose from a variety of designs, colors, and logos, giving them the flexibility to match their racket with personalized gear.

At Dore-Sports, we offer a seamless experience by providing everything needed for padel players under one roof. With our integrated manufacturing and trading services, we ensure competitive pricing, flexibility, and unparalleled quality. Whether it’s a custom-made racket or specialized accessories, Dore-Sports stands as a leader in providing top-notch padel equipment.

As a one-stop pickleball product supplier, D...

As a one-stop pickleball product supplier, D...

As a one-stop pickleball product supplier, D...