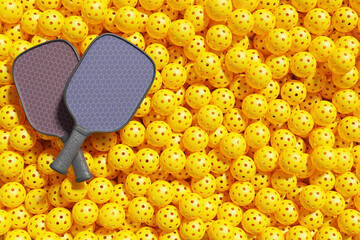

At Dore-Sports, we manufacture high-performance pickleball balls, combining precision engineering with customizable options to meet the diverse needs of players and businesses. As a factory integrating both manufacturing and trade, we not only offer superior pickleball balls but also a one-stop solution for custom accessories, ensuring top-notch quality and flexibility.

Step 1: Material Selection and Preparation

The foundation of a premium pickleball ball lies in its material. High-quality thermoplastic materials, such as durable polyethylene, are selected to ensure the ball is lightweight yet strong enough to withstand repeated impacts. At Dore-Sports, we source the finest raw materials to ensure durability, excellent bounce consistency, and resistance to deformation.

Step 2: Precision Molding Process

Pickleball balls are manufactured using rotational molding or injection molding. At Dore-Sports, we employ advanced rotational molding techniques, where heated plastic material is evenly spread inside a spherical mold to form a seamless, durable shell. This method ensures uniform thickness and eliminates weak spots that could lead to cracking.

Step 3: Hole Drilling for Aerodynamics

One of the most important features of a pickleball ball is its aerodynamics. Each ball requires precise hole drilling to optimize flight stability and balance. The number, size, and distribution of the holes are meticulously calculated to ensure consistent performance in both indoor and outdoor conditions. Dore-Sports utilizes state-of-the-art automated drilling machines to achieve precision, ensuring each ball meets official regulation standards.

Step 4: Seamless Welding and Strength Testing

For balls made using the two-piece injection molding method, the halves are carefully welded together to create a seamless design. This step requires high-temperature fusion and strict quality control to avoid weak bonding. Every ball is then subjected to rigorous strength testing to ensure it can endure fast-paced rallies without losing its structural integrity.

Step 5: Quality Control and Bounce Testing

Before packaging, each pickleball ball undergoes strict quality control tests. These include:

At Dore-Sports, we maintain strict quality assurance procedures to ensure every ball delivers optimal performance.

Step 6: Customization and Branding

To meet the specific needs of brands and businesses, Dore-Sports offers extensive customization services. Clients can personalize their pickleball balls with custom colors, logos, and branding to enhance their market presence. Our advanced printing technology ensures long-lasting, vibrant designs that do not fade or peel over time.

Step 7: Packaging and Accessory Solutions

Once the balls pass all inspections, they are packaged according to customer specifications. We provide a variety of packaging options, from simple bulk packs to custom-designed retail boxes. Additionally, Dore-Sports offers a full range of pickleball accessories, including paddles, bags, and protective cases, creating a complete, one-stop solution for our clients.

At Dore-Sports, we are committed to innovation, precision, and quality. Whether you need tournament-grade pickleball balls or customized promotional products, we provide unmatched expertise and a seamless production process. With our integrated manufacturing and trade capabilities, we offer competitive pricing, flexible customization, and reliable delivery—making Dore-Sports the ultimate partner for your pickleball business.

As a one-stop pickleball product supplier, D...

As a one-stop pickleball product supplier, D...

As a one-stop pickleball product supplier, D...