Pickleball paddles are not just functional tools for the game; they are also a canvas for personalized and creative designs that reflect a player’s style or a brand’s identity. Whether for recreational play or professional tournaments, the printing on a paddle’s face is a key part of its appeal. At Dore-Sports, we specialize in offering a range of printing techniques for pickleball paddles, ensuring that your design is not only visually striking but also durable. In this article, we will explore the most common printing methods used on pickleball paddles and how to choose the right one based on your needs.

1. Pad Printing: The Classic and Cost-Effective Choice

Pad printing is one of the most widely used printing methods in the production of pickleball paddles. This process involves transferring ink onto the paddle’s surface using a silicone pad, which picks up the ink from a plate and then applies it to the curved surface of the paddle.

Advantages of Pad Printing:

Best Use Case for Pad Printing: Pad printing is ideal for high-volume, cost-conscious production where the design requires clear text or simple graphics. It’s also great for promotional products or giveaways, where larger quantities at a lower price point are essential.

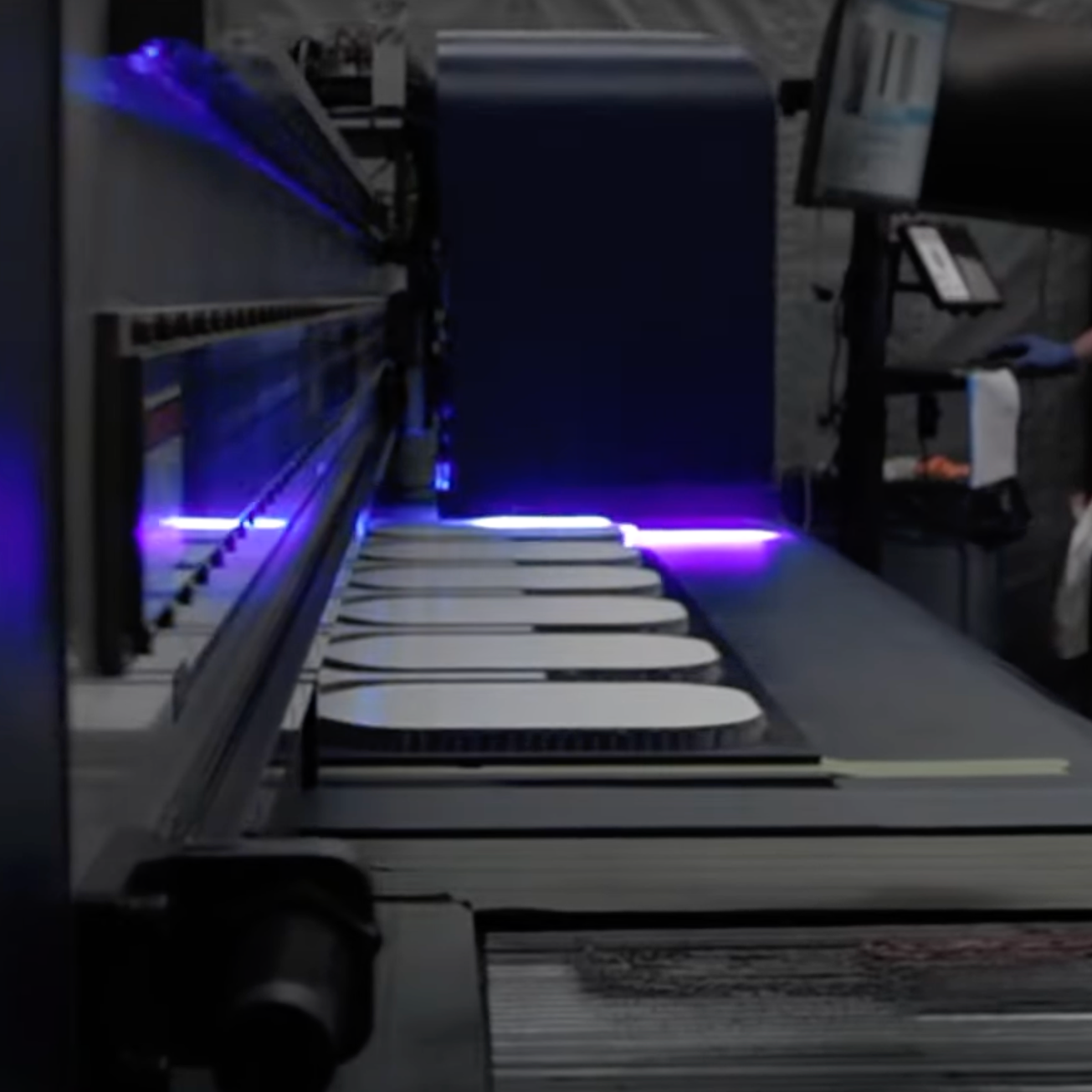

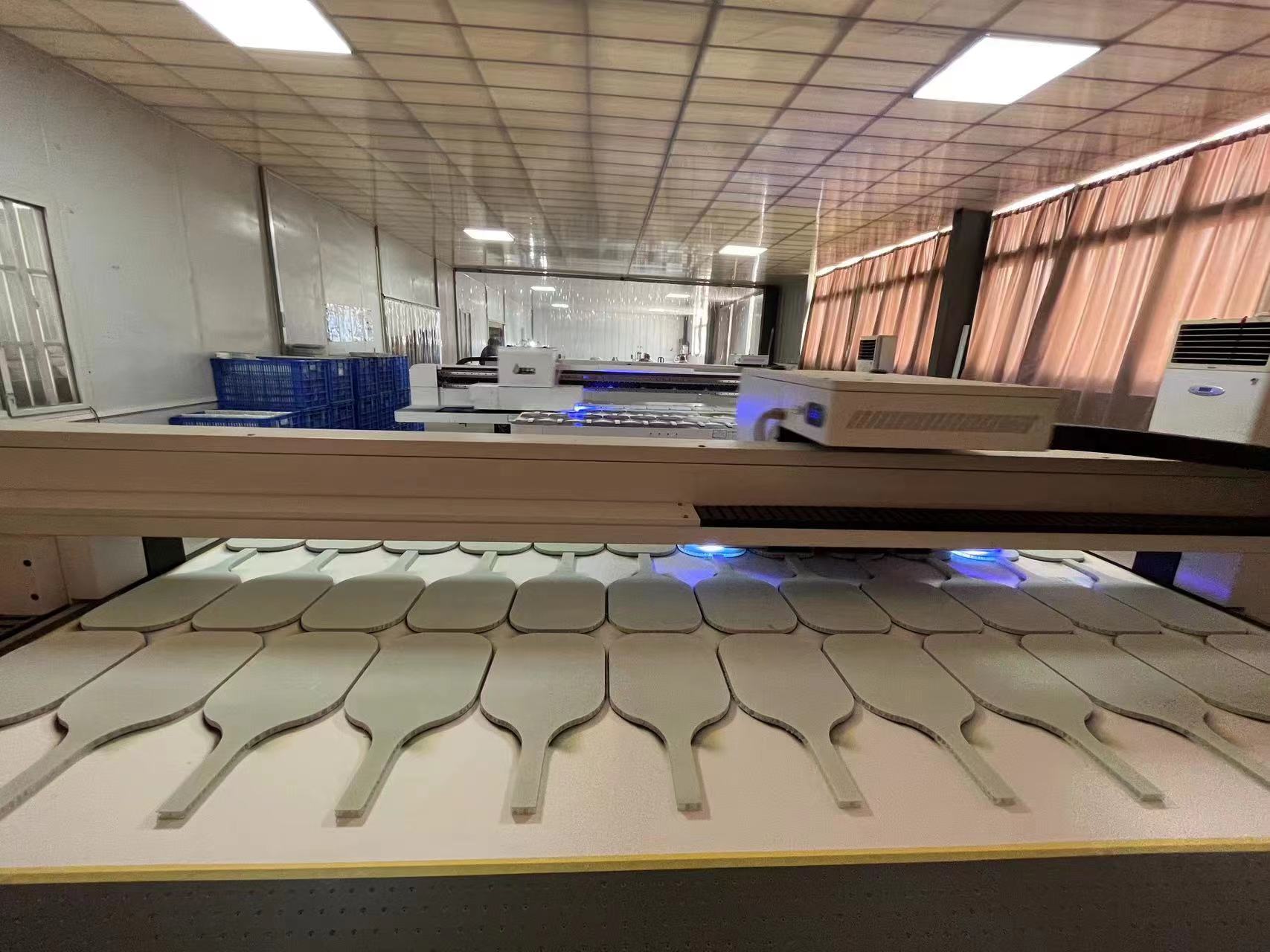

2. UV Printing: Modern and Versatile for Detailed Designs

UV printing is a more advanced and versatile technique that uses ultraviolet light to cure the ink as it is printed onto the paddle. This method allows for high-resolution images with full-color designs, making it a favorite for custom paddles that require complex graphics or vibrant colors.

Advantages of UV Printing:

Best Use Case for UV Printing: UV printing is perfect for businesses or individuals looking for premium designs with full-color images or intricate artwork. It’s especially suited for custom, high-end paddles, limited-edition models, or special promotional items.

3. Screen Printing: Durable and Perfect for Bold Graphics

Screen printing involves pushing ink through a mesh screen to transfer the design onto the paddle. This method is commonly used for larger, bolder designs that require durability and vibrant colors.

Advantages of Screen Printing:

Best Use Case for Screen Printing: Screen printing is best for designs that require high durability and bold color usage. It’s ideal for custom paddles that will see heavy use or for larger production orders where the design is simple but needs to stand out.

Choosing the Right Printing Method:

When choosing a printing method for pickleball paddles, consider the following factors:

Dore-Sports: Your One-Stop Customization Solution

At Dore-Sports, we offer a variety of paddle printing techniques to suit your specific needs. Whether you require a budget-friendly solution for a large quantity of promotional paddles or a high-end, custom-designed paddle with intricate graphics, we can help. Our integrated manufacturing and trading model allows us to produce high-quality paddles and accessories efficiently while offering customization flexibility.

We provide comprehensive solutions, including custom paddle shapes, grip materials, surface textures, and packaging. Our expert team is ready to work with you to bring your vision to life, ensuring that your paddles are not only functional but also visually striking.

As a one-stop pickleball product supplier, D...

As a one-stop pickleball product supplier, D...

As a one-stop pickleball product supplier, D...