The pickleball industry is experiencing an unprecedented boom, with millions of players worldwide fueling the demand for high-quality paddles. Behind the scenes, however, manufacturers face complex challenges related to raw material sourcing, outsourcing production, and logistics optimization. These factors significantly impact cost, production efficiency, and product quality. As a leading pickleball paddle manufacturer, Dore Sports is at the forefront of adapting to these challenges with strategic innovations and supply chain improvements.

Raw Material Sourcing: The Foundation of Quality

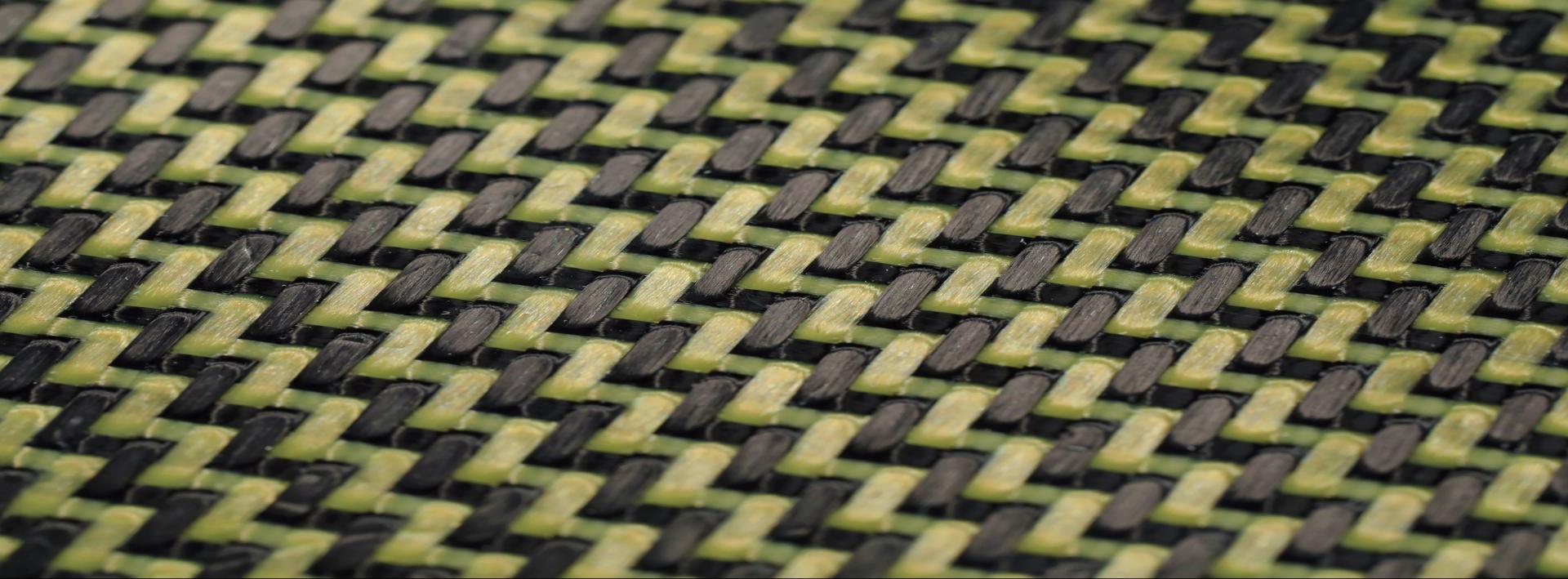

The selection of raw materials plays a critical role in the performance of pickleball paddles. Carbon fiber, fiberglass, Kevlar, and polymer honeycomb cores are among the most commonly used materials. However, fluctuations in material availability and pricing pose ongoing challenges.

To address this, Dore Sports has established long-term partnerships with reliable suppliers to secure high-quality raw materials while minimizing cost fluctuations. Additionally, we are exploring eco-friendly alternatives, such as recycled carbon fiber and plant-based resins, to support sustainability without compromising performance.

Outsourcing Production: Balancing Cost and Quality

Many pickleball paddle brands outsource production to cut costs and increase scalability. While outsourcing can reduce manufacturing expenses, it also introduces risks related to quality control, lead times, and intellectual property protection.

Dore Sports maintains full control over the production process by integrating in-house manufacturing with selective outsourcing. By leveraging advanced CNC machining, hot pressing molding, and automated production lines, we ensure consistent quality, precision, and durability. Additionally, our on-site quality inspection team rigorously monitors outsourced components to meet our high standards.

Logistics Optimization: Reducing Costs and Improving Efficiency

With global demand rising, efficient logistics and supply chain management are crucial for ensuring timely delivery while keeping costs manageable. Manufacturers must consider factors like shipping rates, international trade regulations, and warehouse optimization.

Dore Sports has implemented a multi-tiered logistics strategy, including:

• Regional Warehousing: Establishing fulfillment centers in key markets to reduce shipping time and costs.

• Freight Optimization: Partnering with logistics providers for bulk shipping discounts and efficient route planning.

• Just-in-Time Inventory Management: Reducing excess stock while ensuring steady supply to meet customer demand.

Dore Sports: Leading the Way in Smart Manufacturing

To stay ahead in the competitive pickleball market, Dore Sports continually invests in technology and innovation. Our efforts include:

• AI-Driven Production Planning: Utilizing machine learning to optimize manufacturing schedules and material usage.

• Sustainable Manufacturing: Developing paddles using biodegradable materials and energy-efficient production techniques.

• Customization & Branding Services: Offering OEM & ODM solutions with UV printing, 3D surface textures, and advanced edge protection.

The pickleball paddle industry is shaped by raw material sourcing, production strategies, and logistics efficiency. Manufacturers that successfully navigate these challenges can deliver superior products while maintaining profitability. Dore Sports is committed to innovation, sustainability, and streamlined operations to offer high-quality paddles and reliable services to our customers worldwide.

As a one-stop pickleball product supplier, D...

As a one-stop pickleball product supplier, D...

As a one-stop pickleball product supplier, D...