As pickleball continues its explosive growth worldwide, the demand for high-performance paddles is surging—and so is the need for smarter, faster, and more efficient manufacturing. From China’s booming export factories to America’s high-tech domestic plants, the pickleball paddle industry is entering a new era shaped by automation, AI integration, and intelligent production lines.

The Rise of Smart Factories

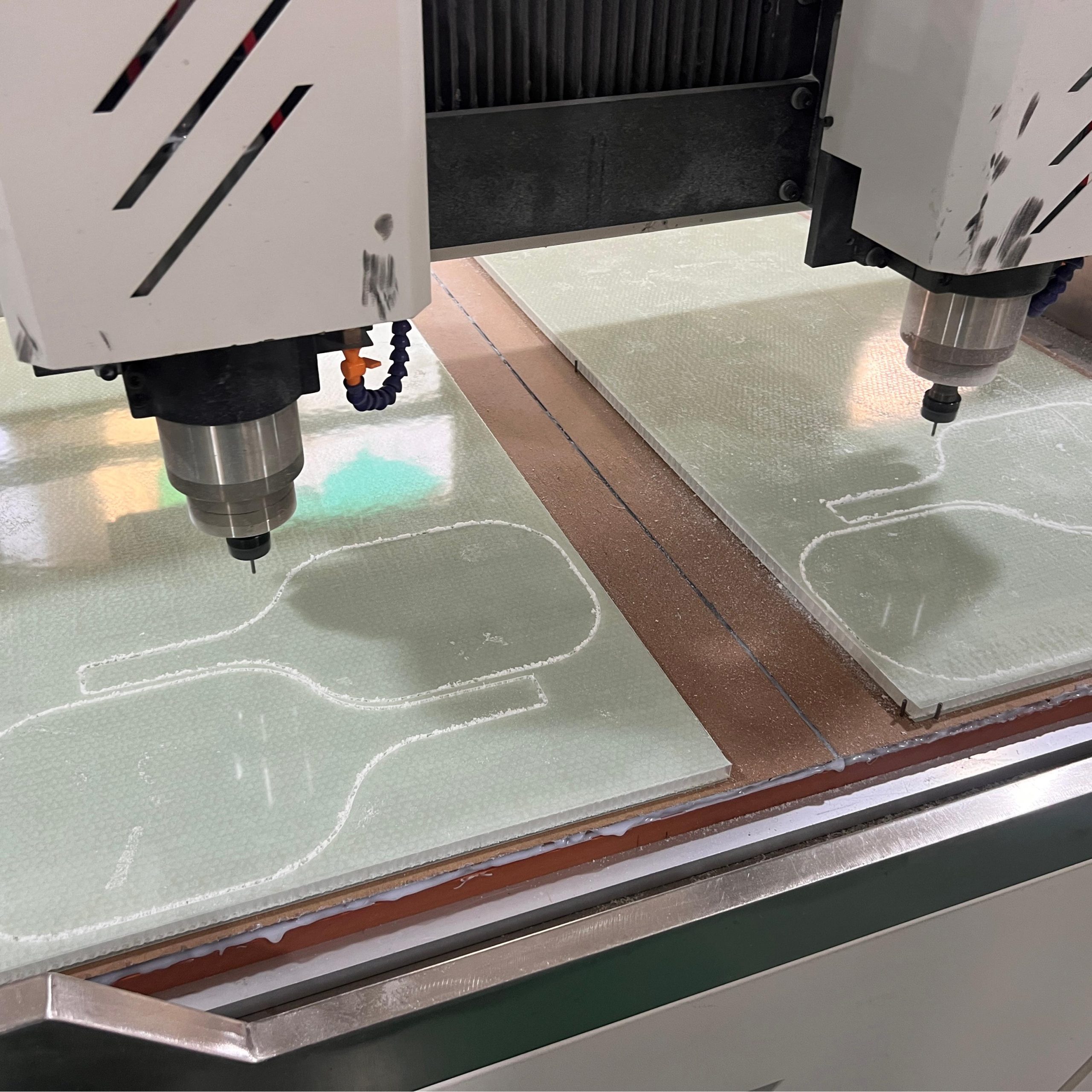

By 2025, factories producing pickleball paddles are increasingly adopting smart manufacturing systems to meet growing global demand. Automation technologies—such as robotic arms for precision cutting, CNC-controlled shaping machines, and AI-assisted quality control systems—are becoming mainstream in both Chinese and U.S. manufacturing facilities.

China, long known as the manufacturing powerhouse, is rapidly shifting from labor-intensive methods to highly automated production floors. Factories are implementing MES (Manufacturing Execution Systems) to track production in real time and integrating IoT devices to monitor machinery health and ensure consistent product quality. These upgrades not only reduce human error but also drastically improve lead times and cost-efficiency.

In the U.S., boutique paddle manufacturers are also embracing smart technologies. AI-driven design software now helps create aerodynamic paddle shapes and optimized core materials. 3D printing is being tested to prototype new paddle forms faster than traditional molds would allow. The result is a wave of innovation tailored to consumer feedback and performance data.

Dore Sports: Leading the Automation Shift

As one of the pioneering manufacturers in the global pickleball paddle supply chain, Dore Sports has strategically invested in automation to improve quality, flexibility, and scalability. With over 13 years of expertise, Dore Sports has embraced CNC machining for shaping consistency, robotic polishing systems to achieve flawless finishes, and AI-integrated inspection tools that catch surface or structural defects at micron levels.

The company has also digitized its customization process, allowing clients to visually preview logo placements, handle styles, and finish textures via an online configurator powered by 3D modeling and rendering. Additionally, Dore’s semi-automated hot-pressing technology ensures reliable fusion of core and face materials—enhancing performance while maintaining cost-efficiency.

“Our smart production lines are not just about machines—they’re about creating agility,” said a Dore Sports spokesperson. “Whether it’s 500 units or 50,000, we can switch materials, specifications, and branding within hours, thanks to modular automation setups.”

Benefits for Global Buyers

The automation revolution delivers multiple advantages for global paddle buyers—whether they’re retailers, sports brands, or training academies. Faster lead times, more consistent product quality, and scalable customization make it easier to meet changing consumer demands. As labor costs rise and efficiency becomes paramount, automated factories provide the winning edge.

Moreover, real-time data analytics from smart production systems allows for constant product refinement. Manufacturers can now track how different materials behave in various climates or user groups, feeding that information back into R&D for future paddle designs.

A Glimpse Into the Future

Looking ahead, the next frontier involves machine learning algorithms that predict material fatigue, autonomous AGVs (automated guided vehicles) for logistics, and fully connected cloud-based ecosystems where design, testing, production, and shipping are seamlessly integrated.

As automation reshapes the industry from China to the U.S., one thing is clear: manufacturers like Dore Sports who embrace technology, flexibility, and customization will lead the pack. The paddles of tomorrow won’t just be better—they’ll be smarter, faster, and made with a level of precision only possible in the era of intelligent manufacturing.

As a one-stop pickleball product supplier, D...

As a one-stop pickleball product supplier, D...

As a one-stop pickleball product supplier, D...