In the booming world of pickleball, one question echoes across boardrooms, factories, and trade shows alike: How can manufacturers optimize costs without sacrificing quality? As the global demand for pickleball paddles soars, especially across North America and Europe, the battle for supply chain efficiency and pricing advantage has never been fiercer. Leading manufacturers like Dore Sports are rising to the challenge, blending strategic sourcing with cutting-edge production technologies to stay ahead in a competitive B2B marketplace.

The Rise of Pickleball and the Cost Pressure on Manufacturers

Pickleball has evolved from a niche sport into a global phenomenon. With millions of new players joining the game each year, the demand for paddles has skyrocketed. For paddle manufacturers, this surge comes with opportunities—and immense pressure. Buyers, especially wholesale distributors and brand owners, are seeking high-performance paddles at more competitive prices.

But raw material costs, labor wages, and international shipping fees have all risen in recent years. So how are top manufacturers coping?

Optimizing the Global Supply Chain

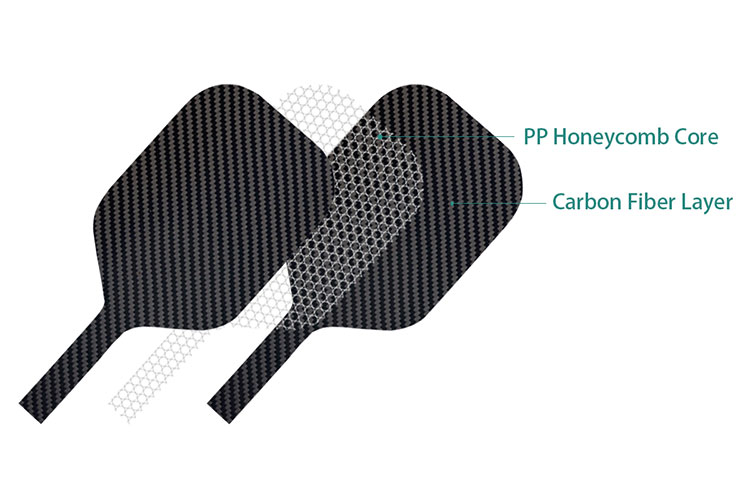

The key to surviving—and thriving—lies in global supply chain optimization. Manufacturers are no longer sourcing materials from a single region. Instead, they’re building multi-country supplier networks to mitigate risks, compare costs, and ensure stability. For instance, some manufacturers procure carbon fiber from Japan, honeycomb cores from South Korea, and outsource grip materials to Southeast Asia, creating a diversified and more cost-effective sourcing strategy.

Dore Sports, a fast-growing pickleball paddle manufacturer based in China, has taken bold steps to transform its supply chain model. The company now works with certified material suppliers across Asia to ensure consistent quality while maintaining pricing flexibility. By negotiating long-term contracts and investing in bulk procurement, Dore Sports reduces costs that would otherwise be passed on to buyers.

Smart Manufacturing: Where Technology Meets Efficiency

In addition to supply chain strategy, technological innovation plays a vital role in cost optimization. Dore Sports recently upgraded its production lines with semi-automated lamination and cutting systems, significantly reducing human error and material waste. This lean manufacturing approach has helped improve production speed while keeping defect rates to a minimum.

The company also introduced RFID tracking systems within its factories to monitor material usage and machine performance in real time. These insights allow for predictive maintenance, avoiding unexpected downtimes and improving production consistency—another crucial factor in fulfilling large B2B orders on time.

Customization Meets Scale

Another major cost-related challenge is balancing mass production with customization, especially for private label brands. Dore Sports tackled this by building flexible modular production cells that can quickly switch between paddle shapes, core types, and surface textures.

This hybrid approach allows the company to support small-batch customization without disrupting large-scale OEM/ODM production—lowering the per-unit cost while maintaining tailored services. It's a game-changing move that appeals to startup brands and large distributors alike.

The Future: Sustainability and Smart Logistics

Looking forward, Dore Sports is investing in eco-friendly materials and carbon-neutral production practices, anticipating future regulatory shifts and brand preferences. The company has begun using recyclable edge guards and biodegradable packaging, aligning with international buyers who prioritize sustainability.

On the logistics side, Dore Sports partners with fulfillment centers in the U.S. and Europe to enable faster delivery at lower cost, bypassing traditional trade bottlenecks and reducing final-mile delivery expenses for clients.

The global competition among pickleball paddle manufacturers is not just about who can make the best paddle—but who can do it smarter, faster, and more cost-effectively. With innovative manufacturing systems, optimized sourcing, and a clear vision for future growth, Dore Sports is proving that cutting costs doesn’t have to mean cutting quality. For B2B buyers seeking reliability, value, and long-term partnership, these are the manufacturers to watch.

As a one-stop pickleball product supplier, D...

As a one-stop pickleball product supplier, D...

As a one-stop pickleball product supplier, D...